Innovative Customized Automation Solutions

In today's competitive manufacturing landscape, generic automation solutions often fall short of achieving optimal efficiency and productivity. To truly excel, manufacturers must embrace a paradigm shift towards Innovative Customized Automation Solutions tailored to the unique demands of their specific parts and production lines.

A Foundation of Deep Understanding:

Our approach begins with a meticulous analysis of:

Part Characteristics:

- Geometric Complexity: Evaluating intricate shapes, delicate features, and dimensional tolerances.

- Material Properties: Understanding material characteristics such as hardness, flexibility, and temperature sensitivity to design appropriate handling mechanisms.

Production Line Dynamics:

- Process Flow: Analysing the entire production process, identifying bottlenecks, and pinpointing areas ripe for automation optimization.

- Production Volume and Speed: Determining production targets and cycle times to design systems that deliver high throughput while maintaining exceptional accuracy.

Engineering Innovation: Beyond the Conventional:

We move beyond off-the-shelf solutions by:

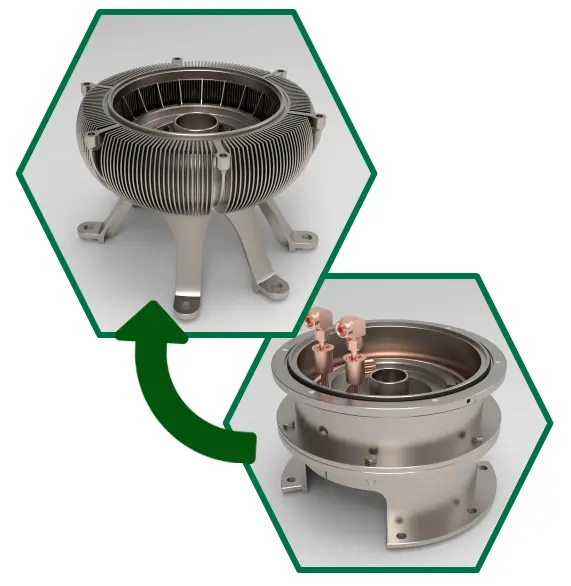

- Developing Custom Mechanisms: Designing and engineering innovative parts specifically tailored to handle challenging requirements with precision and dexterity.

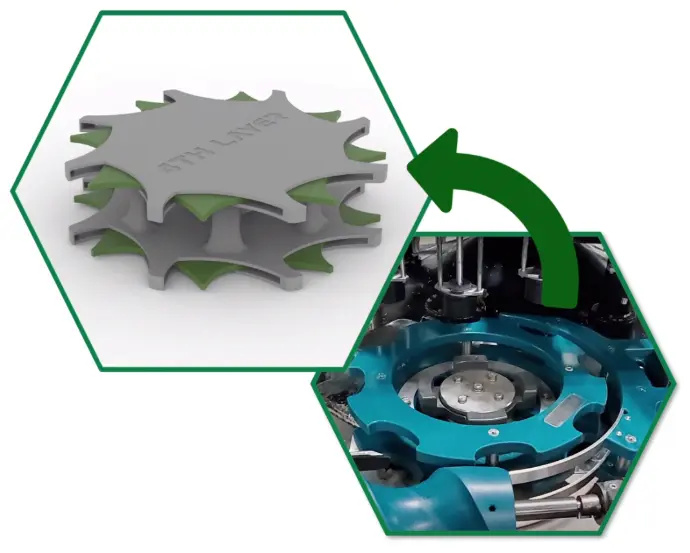

- Creating Customized Indexing and Positioning Systems: Developing high-precision indexing and positioning systems that ensure accurate and synchronized movement of parts throughout the production line.

- Leveraging Advanced Engineering Principles: Applying principles of kinematics, dynamics, and materials science to design robust, efficient, and reliable automation systems.

A Commitment to Excellence:

- Rigorous Prototyping and Testing: Utilizing rapid prototyping techniques and conducting thorough testing to validate design assumptions, refine performance, and ensure optimal functionality.

- Data-Driven Optimization: Continuously analysing production data to identify areas for improvement and iteratively refine the automation solution for enhanced performance and efficiency.

- Collaboration and Communication: Fostering close collaboration with clients to understand their unique needs, address their concerns, and deliver solutions that exceed expectations.

By embracing this approach to customized mechanical automation, manufacturers can:

- Significantly enhance production efficiency and throughput.

- Reduce production costs and minimize waste.

- Improve product quality and consistency.

- Gain a significant competitive advantage in the market.

We are committed to partnering with our clients to develop and implement truly innovative mechanical automation solutions that drive operational excellence and unlock the full potential of their manufacturing processes.